Other folks were the usage of flat, ribbonlike fabrics, akin to reed strips, to make woven baskets for hundreds of years. This weaving approach has reemerged as one way for engineers to create textile and upholstery buildings with complicated geometry. Whilst gorgeous and complex, those baskets can be unusually sturdy.

We’re a staff of buildings and fabrics scientists on the College of Michigan. We needed to determine how basketlike buildings that use conventional weaving tactics can also be so robust, load-bearing and resilient.

To discover the resilience of baskets, we designed a chain of small woven devices that may be assembled into greater buildings. Those woven designs supply virtually the similar stiffness as nonwoven buildings, akin to plastic containers. Additionally they don’t fracture and fail when bent and twisted the best way nonwoven, steady methods (produced from a continuing sheet subject matter) do.

Our basketlike woven buildings have many attainable packages, together with tiny robots which might be very injury resilient – those robots can also be run over through a automobile and nonetheless don’t fail. Lets additionally make woven garments to lend a hand offer protection to other people from serious affects akin to automobile crashes. We made those woven buildings the usage of Mylar (one of those polymer subject matter), wooden and metal.

Basket weaving as a tradition has been round for hundreds of years.

Mlenny/iStock by the use of Getty Photographs

Checking out woven baskets

Early people made baskets through weaving slim strips of bark or reeds, and a few Indigenous societies use those tactics these days. Basket weaving used to be an effective option to flip one-dimensional strips into three-d packing containers.

This geometric receive advantages is an instantaneous motivation for basket weaving, however in our learn about revealed in August 2025 in Bodily Evaluate Analysis, we needed to determine whether or not basket weaving can give greater than aesthetic worth in fashionable science and engineering.

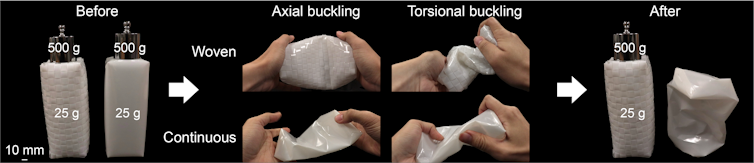

In our experiment, we when compared woven and nonwoven packing containers that had the similar general form and have been fabricated the usage of an identical quantity and form of fabrics.

The “ribbons” we used have been 10 millimeters vast and two-tenths of a millimeter thick. They have been at all times woven in the similar over/beneath/over/beneath development. We wove baskets from the flat ribbons after which created fashions the usage of 3-D scans of those woven packing containers that helped us read about the underlying similarities and variations between the woven and steady buildings.

We discovered that those packing containers had equivalent stiffness to packing containers no longer produced from woven fabrics, and so they additionally went again to their preliminary form when we bent or twisted them.

When evaluating oblong bins manufactured from woven sheets of Mylar polyester ribbons and a continuing sheet of the similar subject matter, the woven construction may nonetheless undergo a load after present process compression (axial buckling) and twisting (torsional buckling), whilst the continual sheet may no longer. Those buildings are manufactured from Mylar (one of those polymer subject matter).

Tu & Filipov, 2025

Whilst you position a heavy object on a woven construction, the ribbons are basically being stretched as a substitute of bent. This stretching makes them stiff as a result of ribbons are a lot stiffer when they’re stretched in comparison to bent. On best of that, the ribbons aren’t rigidly hooked up in woven buildings, which supplies them their atypical resilience.

Through harnessing basket-weaving tactics, engineers can doubtlessly create higher fabrics for automobiles, shopper units akin to smartwatches, and comfortable robots, which might be robots produced from comfortable fabrics as a substitute of inflexible ones. Necessarily, those tactics may strengthen any software when the fabric must be stiff and resilient.

What’s subsequent

Our analysis staff continues to be exploring a couple of large, unanswered questions on those woven baskets.

First, we wish to know how the geometry of the woven baskets determines their stiffness and resilience, and create an analytical or numerical style to explain this courting. We’d then like to make use of that style to design woven buildings that are compatible a goal stiffness and resilience. Maximum woven baskets are home made as a result of their geometry is complicated and hard for a gadget to fabricate.

2d, we’d like to determine learn how to create a gadget that may fabricate woven baskets autonomously. Automatic machines can produce two-dimensional woven materials, however we’d love to discover ways to modernize and digitalize the traditional craft of three-d basket weaving.

3rd, we wish to know how to combine digital fabrics into three-d basket weaving to create next-generation robot textiles. Those robot textiles may sense, actuate, transfer round, undergo a load, keep resilient to unintended overload and safely engage with people on the similar time.

Basket-weaving analysis and packages

Ours isn’t the one learn about exploring the complicated geometry of basket weaving and the possibility of making use of basket-weaving tactics to architectural design.

For instance, researchers teamed up with an artist to tweak a well-liked basket-weaving means, discovering techniques to weave the ribbons and bring any curvature they desired. Later, the similar analysis staff used this technique to manufacture woven domes. They discovered that they may song the stiffness and steadiness of woven domes through various the curvature of the ribbons.

In every other related learn about, researchers constructed algorithms that optimized the scale, form and curvature of ribbons, then used the ones ribbons to weave in combination a geometrically subtle construction.

Our new paintings and those different groups’ paintings is striking a contemporary spin on generation that has most probably been round because the break of day of humanity.