The phrase “local” has grow to be synonymous with sustainability, whether or not it’s meals, garments or the fabrics used to build constructions. However whilst customers can most likely pass to an area lumberyard to shop for lumber from sustainably grown bushes lower at within reach sawmills, no person asks for native glass.

In the event that they did, it might be arduous to provide a solution.

The uncooked fabrics that pass into glass – silica sand, soda ash and limestone – are herbal, however the resources of the ones fabrics are infrequently identified to the consumer.

The method during which sand turns into sheets of glass is incessantly a ways from clear. The sand, which makes up over 70% of glass, may come from a far off riverbed, lakeshore or inland limestone outcrop. Sand with no less than 95% silica content material is named silica sand, and handiest the purest is appropriate for architectural glass manufacturing. Such sand is located in restricted spaces.

Klondike Park, outdoor St. Louis, was once as soon as a mine for St. Peter sandstone, utilized in glass manufacturing. This is likely one of the few U.S. places with 99% natural silica.

Aki Ishida

If the glass is colorless, its doable resources are much more restricted, as a result of colorless low-iron glass – popularized through Apple’s flagship shops and comfort towers all over the world – calls for 99% natural silica sand.

Glass manufacturing in Venice

The mysteries of glass manufacturing have historical precedent that may be traced again to business secrets and techniques of the Venetian Empire.

Venice, in particular the island of Murano, was the middle for glass manufacturing in large part because of its strategic location for uploading uncooked fabrics and manufacturing technology and exporting coveted glass items.

From the eleventh to the sixteenth centuries, the secrets and techniques of glassmaking have been safe through the Venetians till 3 glassmakers have been smuggled out through King Louis XIV of France, who implemented the era to create the Palace of Versailles’ Corridor of Mirrors.

The Palace of Versailles’ famed Corridor of Mirrors was once made through glass artisans educated through the Venetians.

Myrabella/Wikimedia Commons, CC BY-SA

Venice was once an another way not going location for glassmaking.

Neither the principle fabrics of sand and soda ash (sodium carbonate) nor the firewood for the medieval Venetian glassmakers have been discovered within the town’s speedy neighborhood. They have been transported from the riverbeds of the Ticino River in Switzerland and the Agide River, which flows from the Austria-Switzerland border to the Adriatic Sea south of Venice. Soda ash, which is had to decrease the melting level of silica sand, was once introduced from Syria and Egypt.

So Venetian glass manufacturing was once no longer native; it was once depending on valuable sources imported from afar on ships.

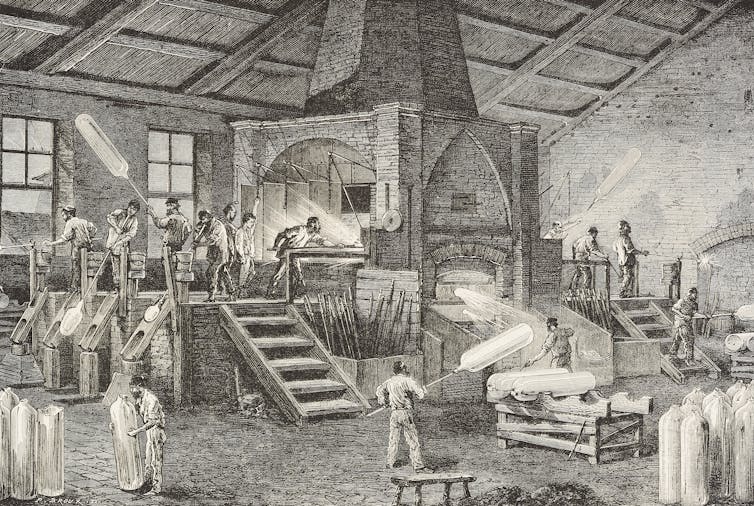

Glassmaking has been a labor- and fuel-intensive procedure. This engraving from 1877 presentations the manufacturing of glass cylinders, which can be lower and unrolled to make glass sheets.

L’Illustrazione Italiana, No 51/De Agostini by the use of Getty Photographs

Emerging call for for low-iron, seamless glass

Previously few many years, low-iron glass, identified for its colorlessness, has grow to be the recent image of top-end structure. The glass seems to vanish.

Low-iron glass is constructed from ultrapure sand this is low in iron oxide. Iron reasons the fairway tint noticed in odd glass. In structure, low-iron glass doesn’t have an effect on the efficiency – handiest the illusion. However it’s prized.

Maximum glass has a greenish tint, led to through iron oxide within the sand. Low-iron glass is extra transparent, however the elements come from unique sand mines, which is able to imply extra transportation emissions, in particular for enormous panels produced in a restricted selection of factories.

Bluecinema/E+ by the use of Getty Photographs

Within the U.S., this kind of sand is located in a couple of places, essentially in Minnesota, Wisconsin, Illinois and Missouri, the place sand as white and advantageous as sugar – thus referred to as saccharoidal – is mined from St. Peter sandstone. Different places the place it may be discovered all over the world come with Queensland in Australia and portions of China. Much less natural sand will also be purified through strategies comparable to acid washing or magnetic separation.

In all probability no company has popularized low-iron and seamless glass in structure greater than the era large Apple.

Glass has grow to be basically connected with Apple’s merchandise and structure, together with its flagship shops’ dear and bold experiments in architectural makes use of of glass.

Apple’s first showroom, finished in Soho in New York in 2002, showcased all-glass stairs that have been reinforced with hurricane- and bullet-resistant plastic interlayers sandwiched between 5 sheets of glass. The treads connect to all glass partitions with a hockey puck-size titanium {hardware}, making each the glass stairs and the consumers seem to flow.

Apple’s New York flagship retailer, dubbed the Dice, was once inbuilt 2006 with 90 panels of low-iron glass, then rebuilt in 2011 with 15 panels.

Ben Hider/Getty Photographs

The corporate’s iconic flagship retailer close to New York’s Central Park is an all-glass dice measuring 32½ toes (10 meters) on each and every aspect and serving as a vestibule to the shop underneath. The primary model was once finished in 2006 the use of 90 panels, which was once a technical feat. Then, in 2011, Apple reconstructed the dice in the similar location, identical length, however with handiest 15 panels, minimizing the selection of seams and {hardware} whilst maximizing transparency.

Nowadays, low-iron glass has grow to be the usual for high-profile structure and those that can manage to pay for it, together with the “pencil towers” in Big apple’s Billionaires’ Row.

New high-rises just like the supertall towers in New York’s Billionaire’s Row are in large part clad flooring to ceiling in glass.

Aerial_Views/E+ by the use of Getty Photographs

Glass’s local weather affect

Glass partitions not unusual in high-rise constructions as of late produce other drawbacks. They lend a hand to warmth up the room throughout an increasing number of scorching summers and give a contribution to warmth loss in iciness, expanding dependence on synthetic cooling and heating.

The glassmaking procedure is power in depth and depends on nonrenewable sources.

To convey sand to its molten state, the furnace should be heated to over 2,700 levels Fahrenheit (1,500 levels Celisus) for so long as 50 hours, which calls for burning fossil fuels comparable to herbal fuel, freeing greenhouse gases. As soon as heated to that temperature, the furnace runs 24/7 and isn’t close down.

Glass producer Pilkington presentations how glass is made.

The soda ash and limestone additionally free up carbon dioxide throughout melting. Additionally, glass manufacturing calls for mining or generating nonrenewable herbal sources comparable to sand, soda ash, lime and gasoline. Transporting them additional will increase emissions.

Manufacturing and fabrication of extra-large glass panels depend on specialised apparatus and happen handiest at a restricted selection of crops on this planet, that means transportation will increase the carbon footprint.

Architectural glass could also be tricky to recycle, in large part because of the exertions fascinated with setting apart glass from the development meeting.

Even supposing glass is touted as infinitely recyclable, handiest 6% of architectural glass is downcycled into glass merchandise that require much less purity and precision, and nearly none is recycled into architectural glass. The remaining leads to landfills.

The expanding call for for glass this is colorless, more extensive and seamless contributes to glass’s sustainability drawback.

This 99% natural silica, a sugarlike sand, comes from a St. Peter sandstone mine as soon as used for glassmaking. It’s now Klondike Park in St. Charles County, Mo.

Aki Ishida

How are we able to make glass extra sustainable?

There are methods to scale back glass’s environmental footprint.

Researchers and firms are running on new varieties of glass that might decrease its local weather affect, comparable to the use of fabrics that decrease the volume of warmth vital to make glass. Changing herbal fuel, usually utilized in glassmaking, with less-polluting energy resources too can scale back emissions.

Low-e coatings, a skinny coat of silver sprayed onto a pitcher floor, can lend a hand scale back the volume of warmth that reaches a development’s internal through reflecting each the visual heat and light, however the coating can’t absolutely get rid of sun warmth achieve.

Other people too can regulate their requirements and settle for smaller and no more ultraclear panels. Call to mind the fairway tint no longer as impure however herbal.