Manufactured chemical compounds and fabrics are vital for almost each side of day by day lifestyles, from life-saving prescription drugs to plastics, fuels and fertilizers. But production those vital chemical compounds comes at a steep calories charge.

Many of those business chemical compounds are derived essentially from fossil fuel-based fabrics. Those compounds are generally very strong, making it tough to change into them into helpful merchandise with out making use of harsh and energy-demanding response prerequisites.

Because of this, remodeling those cussed fabrics contributes considerably to the arena’s total calories use. In 2022, the economic sector ate up 37% of the arena’s general calories, with the chemical business chargeable for roughly 12% of that call for.

Typical chemical production processes use warmth to generate the calories wanted for reactions that happen at excessive temperatures and pressures. An means that makes use of gentle as a substitute of warmth may decrease calories calls for and make allowance reactions to be run underneath gentler prerequisites — like at room temperature as a substitute of maximum warmth.

Daylight represents some of the plentiful but underutilized calories assets on Earth. In nature, this calories is captured via photosynthesis, the place crops convert gentle into chemical calories. Impressed by way of this procedure, our staff of chemists on the Heart for Sustainable Photoredox Catalysis, a analysis heart funded by way of the Nationwide Science Basis, has been running on a device that makes use of gentle to energy reactions repeatedly used within the chemical production business. We revealed our leads to the magazine Science in June 2025.

We are hoping that this system may supply a less expensive path for developing business chemical compounds out of fossil fuels. On the similar time, because it doesn’t depend on super-high temperatures or pressures, the method is more secure, with fewer possibilities for injuries.

Vegetation seize daylight to transform carbon dioxide from the air into carbohydrates, or sugars.

Wattcle, Nefronus/Wikimedia Commons, CC BY-SA

How does our device paintings?

The photoredox catalyst device that our staff has advanced is powered by way of easy LEDs, and it operates successfully at room temperature.

On the core of our device is an natural photoredox catalyst: a specialised molecule that we all know hurries up chemical reactions when uncovered to gentle, with out being ate up within the procedure.

Just like how crops depend on pigments to reap daylight for photosynthesis, our photoredox catalyst absorbs more than one debris of sunshine, known as photons, in a chain.

Those photons supply bursts of calories, which the catalyst retail outlets after which makes use of to kick-start reactions. This “multi-photon” harvesting builds up sufficient calories to drive very cussed molecules into present process reactions that might another way want extremely reactive metals. As soon as the response is whole, the photocatalyst resets itself, in a position to reap extra gentle and stay the method going with out developing additional waste.

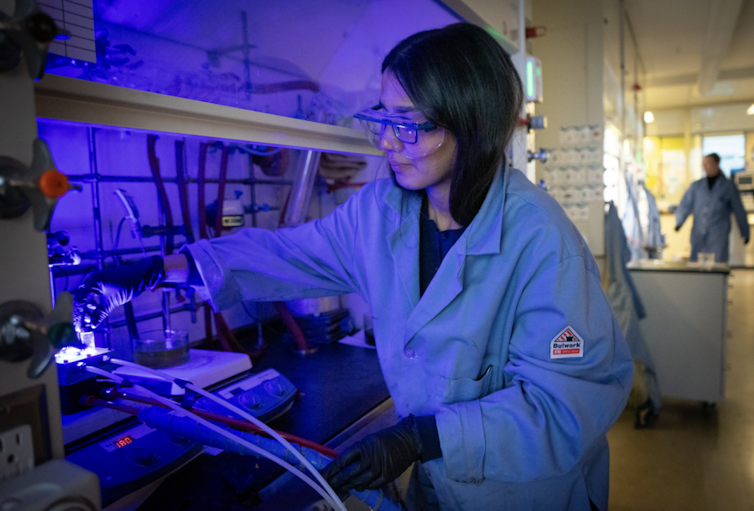

Heart for Sustainable Photoredox Catalysis researcher Amreen Bains plays a light-driven photoredox catalyzed response.

John Cline, Colorado State College Images

Enabling greener chemical production

Our paintings issues towards a long run the place chemical compounds are made the usage of gentle as a substitute of warmth. For instance, our catalyst can flip benzene — a easy part of crude oil — into a sort known as cyclohexadienes. It is a key step in making the construction blocks for nylon. Making improvements to this a part of the method may scale back the carbon footprint of nylon manufacturing.

Consider producers the usage of LED reactors and even daylight to energy the manufacturing of very important chemical compounds. LEDs nonetheless use electrical energy, however they want a long way much less calories when compared with the standard heating strategies utilized in chemical production. As we scale issues up, we’re additionally working out techniques to harness daylight at once, making all of the procedure much more sustainable and energy-efficient.

At the moment, we’re the usage of our photoredox catalysts effectively in small lab experiments — generating simply milligrams at a time. However to transport into business production, we’ll want to display that those catalysts too can paintings successfully at a far higher scale, making kilograms and even lots of product. Checking out them in those larger reactions will make certain that they’re dependable and cost-effective sufficient for real-world chemical production.

In a similar way, scaling up this procedure will require large-scale reactors that use gentle successfully. Construction the ones will first require designing new kinds of reactors that allow gentle succeed in deeper within. They’ll want to be extra clear or constructed otherwise so the sunshine can simply get to all portions of the response.

Our staff plans to stay creating new light-driven ways impressed by way of nature’s potency. Daylight is a ample useful resource, and by way of discovering higher techniques to faucet into it, we are hoping to make it more straightforward and cleaner to provide the chemical compounds and fabrics that fashionable lifestyles depends upon.