Within the context of environmental transition, commercial sectors are going through the problem of researching new strategies of transformation to fortify renewable resources, the use of much less consumption (power, water or uncooked subject material) and by way of developing smaller waste.

Amongst conceivable routes for crossing Petrosource in BioSourcee, fermentation is particularly promising to satisfy the desires of practicality of chemical compounds (mass marketplace, low prices) and particular chemical compounds (niches of chemical compounds (area of interest huge added price).

Microorganisms (micro organism, yeast and fungi) are biotechnological gear of fermentation; They change into uncooked fabrics in pastime merchandise. Penicillium is a filamentous mushroom most famed as a manufacturer of the primary antibiotic, penicillin. Insulin manufacturing Bacterial soybeans Escherichia Coli is any other important instance. To grasp the fermentation procedure, it’s important to select microorganisms that put in force selective metabolic routes to make a molecule pastime and decrease different molecules it has produced.

Additionally it is important to optimize the expansion of microorganisms and the manufacturing of desired molecules within the bioreactor tank, which takes position, particularly adjusting the composition, temperature and dissolved oxygen content material within the atmosphere. On the other hand, now and again the pastime molecule or different molecules produced concurrently poisonous for microorganism produced. Due to this fact, the buildup of ethanol in bioreactor can inhibit yeast metabolism that produces it. This toxicity reduces fermentation efficiency. The best way to conquer those toxicities is to extract a poisonous molecule from bioreactors throughout fermentation growth. It’s the concept of extractive fermentation that goals to take away those restrictions and due to this fact accentuate the manufacturing of molecules of pastime.

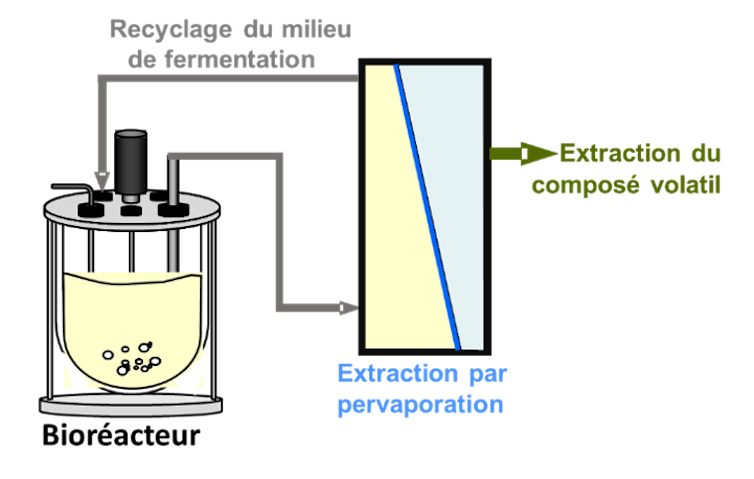

The manufacturing of pastime molecules is maximized by way of its steady removing of bioreactors. Extractive fermentation additionally advantages from the recycling of the fermentation media, which is within the award in bioreactor. Silmamam Representation, which used to be gained by way of the writer

Counting fermentation and extraction calls for the collection of era ideas and extraction tailored to this coupling and optimizing extracting prerequisites to maximise the full efficiency of extractive fermentation. The function is to procure the utmost quantity of the required product.

Leading edge era in commercial biotechnology

Extractive fermentation for generating molecules corresponding to natural acids or aromas used to be made. It’s an cutting edge era in commercial biotechnology.

Carboxylic acids occupy crucial position amongst organic molecules produced by way of fermentation. They feed quite a lot of programs in meals, cosmetics, pharmaceutical, textile and chemical spaces, at Eu and world ranges. Emblematic acid is acetylsalicylic acid, higher referred to as aspirin. Some other instance is dairy acid, manufactured by way of fermentation and is used as a hippo and dragostar style.

New fermentation processes are creating to satisfy the rising call for for the manufacturing of biosour molecules of pastime. That is the case with 3-hydroxypropionic acid or 3-HP acid. This acid has distinguishing and acids and alcohol. This particular function facilitates transformation into a mess of alternative compounds of pastime; Because of this we are saying that 3-HP acid is a platform or synthon molecule. To provide 3-HP acids, acetic micro organism have fascinating capability: their skill to oxidize alcohol for natural acids. This lets them biooconize 1.3 propanioniol in 3-HP acids.

Our analysis within the “Microbiological processes, the stabilization, separation” of SOFFOOD is conceivable to procure selective oxidation of this alcohol in 3-HP yield throughout the expansion of acetobacter cerevisae bacterial lines containing glycerol as a carbon supply.

Coupling and fermentation extraction

Notice Within the switch that this result’s all this is promising as a result of Glycerol co-producting is an commercial manufacturing strategy of biodiesel. All through fermentation, the buildup of 3-HP acid generates the acidification of our environment by which micro organism develops. This acidification in addition to the buildup of metabolic intermediate 3-HP acid biosynthesis strongly inhibits the metabolism of Acetobacter cerevisae and thus generating 3-HP acid. To restrict those inhibitions, now we have studied the implementation of a 3-HP acid extraction device in coupling to fermentation. Now not best do micro organism most often don’t expand in most cases, however extraction additionally promotes microbial metabolism in 3-HP acid manufacturing. So we advanced reactive membrane extraction to selectively recuperate all manufacturing acids. It’s parallel, the second one membrane is meant to regenerate the bioreactor extraction section to recycle it.

Extractive fermentation device the use of bioreactor and membrane touch. Equipped the writer

Different extractive fermentation processes had been showed for the manufacturing of risky natural compounds (VOC). Of serious selection, those rides are most commonly found in chemical, meals, pharmaceutical and beauty industries. Those compounds belong to a number of chemical households (alcohol, esters, ether, aldehyde, ketone, carboxylic acid, and so forth.) and be offering quite a lot of purposeful homes. A few of these VOCs have top added price within the aroma and fragrance sector (as much as a number of thousand euros / L). Molecules produced by way of biotechnological direction are commercially aggressive, although their prices are 10 to 100 instances upper than their artificial colleagues because of the entire asked “natural” cited.

We find out about an extractive VOC strike like a 2-phenylethane used as a preservative in pharmaceutical merchandise and perfumery because of the smell of roses and solvents of ethyl acetate, which is used as a solvent for varnishes, dry cleansing merchandise. Those compounds can also be produced by way of number of microorganisms, corresponding to yeasts which are ready to assimilate quite a lot of substrates (Ceboza, Hydrolysis, Malthosis, Sugar Manufacturing facility, Positioned Line Business, and so forth.). Given the microbial manufacturing of VOC, problems associated with their mobile toxicity additionally offered a joint for extraction and fermentation as an cutting edge technique for intensifying biodies. Because of their hydrophobic and risky persona, the VOC can be drawn and a certification – by way of the process the use of organ-selective membranes and which is best particularly neatly in fermentation couplings.

Unstable molecules can also be regularly extracted throughout fermentation because of the window the use of an organ-selective membrane. Equipped the writer

Rising world call for for merchandise from Bio -Primarily based will accelerate the advance of fermentation at the commercial scale. For fermentation processes that will probably be powerful in this scale, should be amplified and mixed with different processing processes, throughout the optimization manner that quilt technical, financial and environmental efficiency. Those processes can get pleasure from the appliance of extractive fermentation. Here’s the function of creating inventions that meet social wishes and supporting the advance of round and sustainable bioeconomics.