Concrete is throughout you – within the basis of your house, the bridges you force over, the sidewalks and structures of towns. It’s regularly described because the second-most used subject matter by way of quantity on Earth after water.

However the way in which concrete is made nowadays additionally makes it a significant contributor to weather trade.

Portland cement, the important thing part of concrete, is answerable for about 8% of world greenhouse fuel emissions. That’s as it’s made by way of heating limestone to prime temperatures, a procedure that burns a considerable amount of fossil fuels for power and releases carbon dioxide from the limestone within the procedure.

Portland cement: A greenhouse fuel downside

Cementlike ingredients had been utilized in building for 1000’s of years. Architects have discovered proof in their use within the pyramids of Egypt and the structures and aqueducts of the Roman Empire.

The Portland cement repeatedly utilized in building nowadays used to be patented in 1824 by way of Joseph Aspdin, a British bricklayer.

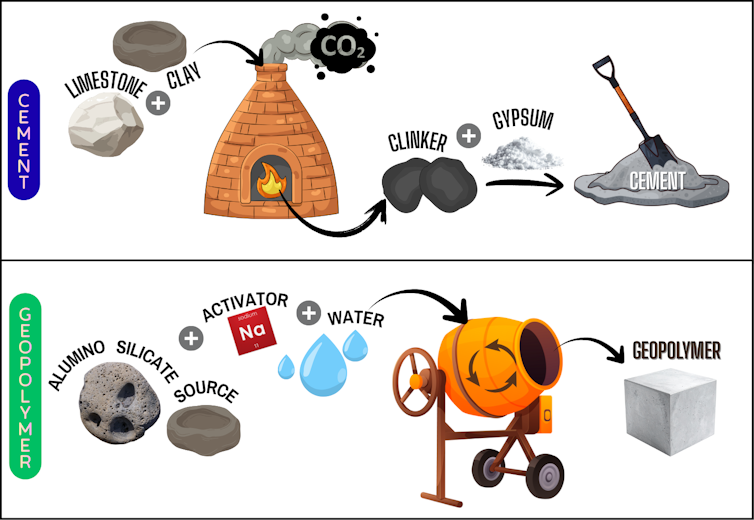

Fashionable cement preparation begins with crushing the excavated uncooked fabrics limestone and clay after which heating them in a kiln at round 2,650 levels Fahrenheit (about 1,450 levels Celsius) to shape clinker, a difficult, rocklike residue. The clinker is then cooled and flooring with gypsum right into a nice powder, which is named cement.

About 40% of the carbon dioxide emissions from cement manufacturing come from burning fossil fuels to generate the prime warmth had to run the kiln. The remaining come as the warmth converts limestone (calcium carbonate) to lime (calcium oxide), liberating carbon dioxide.

In all, between part a ton and 1 ton of greenhouse fuel is launched in keeping with ton of Portland cement. Cement is a binding agent that, blended with water, holds mixture in combination to create concrete. It makes up about 10% to fifteen% of the concrete combine by way of weight.

Choice applied sciences can decrease emissions

As populations, towns and the desire for brand spanking new infrastructure amplify, the usage of cement is rising, making it essential to seek out possible choices with decrease environmental prices.

As inhabitants has greater, annual world Portland cement manufacturing has risen with it.

Hao Chen, et al., 2025, CC BY-NC-ND

Some tactics for lowering carbon dioxide emissions come with substituting one of the clinker – the onerous residue generally comprised of limestone – with supplementary fabrics corresponding to clay, or fly ash and slag from industries. Different strategies scale back the volume of cement by way of blending in waste sawdust or recycled fabrics like plastics.

The long-term answer for lowering cement’s emissions, alternatively, is to interchange conventional cement totally with possible choices. One possibility is geopolymers comprised of earthen clay and business wastes.

Geopolymers: A extra climate-friendly answer

Geopolymers will also be made by way of blending claylike fabrics which might be wealthy in aluminum and silicon minerals with a chemical activator via a procedure referred to as geopolymerization. The activator transforms the silicon and aluminum right into a construction that may appear to be cement. All of it will occur at room temperature.

The key distinction between cement and geopolymer is that cement is basically fabricated from calcium, while geopolymers are fabricated from silicon and aluminum with some conceivable calcium of their construction.

How the manufacturing of Portland cement and geopolymers examine.

Alcina Johnson Sudagar, CC BY-NC

Those geopolymers had been discovered to own prime power and sturdiness, together with resilience in freeze-thaw cycles and resistance to warmth and fireplace, that are essential necessities in building. Research have discovered that some geopolymers may give related if now not higher power than conventional cement and, as a result of they don’t require warmth the way in which clinker does, they may be able to be produced with considerably decrease greenhouse fuel emissions.

Geopolymers will also be constituted of plenty of uncooked fabrics wealthy in aluminum and silicon, together with earthen clays, fly ash, blast furnace slag, rice husk ash, iron ore wastes and recycled building brick waste. Geopolymer generation will also be tailored relying at the clay or business waste in the community to be had in a area.

A temporary historical past of cement and geopolymers. Geopolymer World.

An added good thing about geopolymers is that adjustments to the combination can produce a variety of options.

For instance, I and my co-researchers on the College of Aveiro in Portugal added a small quantity of cork trade waste – the leftovers from developing bottle corks – to clay-based geopolymer and located it would enhance the power of the fabric by way of as much as twofold. The cork debris stuffed the areas within the geopolymer construction, making it denser, which greater the power.

In a similar way, components corresponding to sisal fibers from the agave plant, recycled plastic and metal fibers can trade geopolymer homes. The components don’t take part within the geopolymerization procedure however act as fillers within the construction.

The construction of geopolymers will also be designed to behave as adsorbents, attracting poisonous metals in wastewater and taking pictures and storing radioactive wastes. Particularly, incorporating fabrics like zeolite which might be herbal adsorbents within the geopolymer construction can lead them to helpful for such programs as smartly.

The place geopolymers are used now

Geopolymers had been utilized in many kinds of building, together with roads, coatings, 3-D printing, coastal environmental coverage, the metal and chemical industries, sewer rehabilitation and constructing radiation shielding and rocket launchpad and bunker infrastructure.

One of the vital earliest examples of a contemporary geopolymer concrete undertaking used to be the Brisbane West Wellcamp airport in Australia.

It used to be inbuilt 2014 with 70,000 metric heaps of geopolymer concrete, which used to be estimated to have lowered the undertaking’s carbon dioxide emissions by way of up to 80%.

The geopolymer marketplace is recently estimated to be between US$7 billion and $10 billion, with the most important enlargement within the Asia-Pacific area.

Analysts have estimated that the marketplace may develop at a charge of 10% to twenty% in keeping with yr and succeed in about $62 billion by way of 2033.

In numerous nations, greenhouse fuel rules and green-building certifications are anticipated to fortify the ongoing enlargement of geopolymers within the building trade.

Increasing the usage of cement possible choices

The benefit of the usage of business wastes in geopolymers is a double-edged sword, alternatively. The composition of business wastes varies, so it may be tough to standardize the processing strategies. The geopolymer parts want to be jumbled together specific ratios to reach desired homes.

Generating the activator for the geopolymer, generally achieved in chemical amenities, can elevate the price and give a contribution to the carbon footprint. And the long-term information about those fabrics’ balance is most effective now being evolved given their newness. Additionally, those geopolymers can take longer to set than cement, regardless that the environment time will also be speeded up by way of the usage of uncooked fabrics that react briefly.

Growing inexpensive, naturally to be had activators like agricultural waste rice husk with sustainable provide chains may assist decrease the prices and environmental have an effect on. Additionally, printing the recipe at the uncooked subject matter packaging may assist simplify the activity of figuring out the blending ratio so geopolymers will also be extra broadly used with self belief.

Despite the fact that geopolymer generation has some drawbacks, those low-carbon possible choices have nice attainable for lowering emissions from the development sector.