Solar energy has a dismal facet: panels are nonetheless constructed to be thrown away, and we possibility making a mountain of waste that locks away precious minerals.

The sector already faces as much as 250 million tonnes of sun waste through 2050, as panels put in all the way through the sun growth of the 2000s and 2010s achieve the top in their provider existence.

Those panels weren’t designed to be repaired, refurbished, or disassembled. Certainly, present recycling processes principally extract glass and aluminium, whilst the fabrics that elevate the absolute best financial and strategic price equivalent to silver, copper and high-grade silicon are in most cases misplaced within the procedure.

The business now faces a slender window to reconsider. With no shift in design, the power transition may just finally end up moving environmental pressures slightly than decreasing them. Development low-carbon era is very important, however low-carbon does now not inherently imply sustainable.

A booming business designed for the unload

The common lifespan of sun modules is set 25 to 30 years. This implies a large wave of installations from the early 2000s is now attaining the top of its existence cycle. International locations with mature sun markets like Germany, Australia, Japan and america are already seeing a pointy build up within the selection of panels being taken out of provider.

The problem lies now not handiest within the scale of the waste but additionally within the very design of the panels. To continue to exist many years of climate, sun panels are constructed through stacking layers of glass, cells and plastic, then bonding them in combination so tightly with robust adhesives that they develop into a unmarried, inseparable unit.

You’ll be able to call to mind a sun panel like an industrial-strength sandwich.

VectorMine / shutterstock

However this sturdiness has a drawback. For the reason that layers are so tightly bonded, they’re exceptionally tough to peel aside, successfully combating us from solving the panels once they smash or improving fabrics when they’re thrown away (the ones fabrics may just generate US$15 billion (£11 billion) in financial price through 2050).

The boundaries of recycling

In the end, recycling will have to be a final lodge as it destroys a lot of the embedded price. That’s as a result of present processes are crude, most commonly shredding panels to get well reasonable aluminium and glass whilst dropping excessive price metals.

For example, whilst silver represents handiest 0.14% of a sun panel’s mass, it accounts for over 40% of its subject material price and about 10% of its overall value. But it’s infrequently recovered when recycling. Throughout usual recycling, sun panels are overwhelmed. The silver is pulverised into microscopic debris that develop into combined with glass, silicon and plastic residues, making it too tough and costly to split.

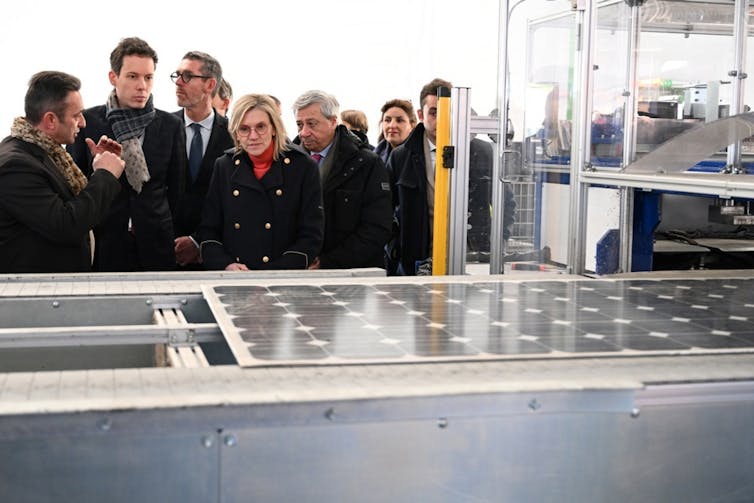

France’s then-minister for power transition visits a sun recycling plant in 2023.

Caroline Blumberg / EPA

That’s why methods that intention to increase the lifetime of sun panels – equivalent to restore and reuse – are hugely awesome to recycling. They maintain the price of those merchandise, and steer clear of the large power value of commercial shredding. They preserve precious fabrics in circulate and cut back the wish to extract new uncooked fabrics. They are able to even generate new income for homeowners. However this round imaginative and prescient is handiest viable if sun panels are designed to be taken aside and repaired.

Designing panels for a round long term

Transferring against such an method manner redesigning panels so they are able to be repaired, upgraded and in the end disassembled with out harmful or destroying the elements within. The theory of designing for disassembly, not unusual in different sectors, is more and more very important for sun too.

As an alternative of everlasting adhesives and entirely laminated layers, panels can also be constructed the usage of modular designs and reversible connections. Elements equivalent to frames, junction containers and connectors will have to be detachable, whilst mechanical fixings or good adhesives that unlock handiest at excessive temperatures can permit glass and cells to be separated extra simply.

Standardising elements and bettering documentation would additional fortify repairers, refurbishers and recyclers during a panel’s existence cycle. Briefly, the following era of sun panels will have to be designed to last more, be repairable, and use fewer important fabrics — now not merely to maximize non permanent power output.

Virtual gear can assist

If you wish to restore or recycle a panel years from now, you’ll wish to know what fabrics it incorporates, what adhesives had been used and the way it used to be assembled. Virtual gear can assist right here through storing knowledge, necessarily appearing like a automobile’s logbook or a affected person’s clinical document.

One promising instance is the EU’s new Virtual Product Passport. Those passports will come with steering on restore choices, disassembly, hazardous components, lifecycle historical past and end-of-life dealing with. They’re going to be offered step by step for precedence product teams from 2027, with additional enlargement to many different merchandise, anticipated against round 2030.

The Virtual Product Passport acts as a static “ingredients list” for a sun panel. It displays what a panel is manufactured from and the way it will have to be treated. Virtual twins, in contrast, serve as extra like a real-time tracking gadget.

Often up to date with efficiency knowledge, they are able to sign when a panel is under-performing, has develop into too dusty, or wishes repairing. Used in combination, those gear can assist technicians establish which portions can also be be repaired or reused and make sure sun panels are safely dismantled on the finish in their existence.

Alternatively, even the most efficient virtual dual isn’t a lot use if the panel itself is glued close and designed for the unload. With out panels which can be constructed to be repaired or taken aside, digitalisation will be offering handiest marginal advantages.

Virtual gear even have their very own environmental footprint, from sensors to knowledge garage, which makes it much more necessary that they fortify in actuality repairable designs slightly than catch up on deficient ones. We will have to reconsider how we design sun panels presently, earlier than lately’s sun growth locks in the next day’s waste drawback.