Annually the trade rejects the a part of the warmth wanted for all its processes. This misplaced power is named waste warmth. Those warmth restoration answers are nonetheless too restricted lately. New gadgets, the usage of warmth pumps and “supercritical” liquids, are evolved.

Cement ovens, drying paper, meals processing … The volume of warmth misplaced lately in business processes are vital. Clearly we wish to do the entirety we will scale back them via optimizing the method and adjusting manufacturing in addition to imaginable to require. However no bodily procedure can reach best possible potency, and if there’s not anything to recuperate warmth, the similar of 7 Megato oil can even burn 28 Megatons CO2 or 6% of the whole CO2 emissions in France.

Strategies for improving misplaced (or deadly) warmth lately basically goal top temperature deposits (above 100 ° C) or require the life of a close-by warmth community (a suite of pipes that may be warmer for instance on brief distances or public constructions, for instance).

To make higher use of this warmth produced in factories, which might constitute a complete tank of about 110 terrace hours in France, and different answers are lately studied.

Waste warmth: thermal power emitted via all industries in lots of bureaucracy

To higher perceive the questions, let’s make a concrete instance, it is a cement manufacturing facility. The tone of cement calls for 3000 megajoul warmth: most effective 40% take in the chemical response between clay and limestone, and a part of the rest 60% may also be reused immediately to magnify fabrics. However warmth misplaced within the setting is estimated between 300 and 1000 megajoules in step with tonne. Realizing that cement plant can produce about 1,500 heaps of cement in step with day, it’s raised between 12 and 37 heaps of gas an afternoon for not anything.

This drawback is far wider than cement vegetation: we discover the meals trade on most sensible, then chemical compounds and plastic, paper and cardboard manufacturing, metal industries and non-metallic fabrics (cement, glass, tiles or bricks). All business sectors together, ovens and dryers constitute 60% of power ate up via the trade in France.

An extra birthday celebration is that this is a excellent section (60%) of power received via burning fossil fabrics, which emit CO2 into the ambience and explains why the trade continues to be answerable for about 17% of France fuel emissions. The purpose is to cut back those emissions via 35% via 2030. And via 81% to 2050. In comparison to 2015.

The waste warmth was once broadcast or recycled throughout the economic procedure since the temperature of a thermal warmth thermal warmth thermal warmth thermal thermal thermal thermal thermal thermal thermal thermal thermal thermal warmth thermal warmth warmth warmth warmth warmth warmth warmth thermal warmth warmth) tall. It’s so fundamental for engineers and researchers to differentiate “low temperature” or “low quality” waste warmth) and so-called “high temperatures” or “high quality” waste warmth above 100 ° C (53 theravatte).

Find out how to recycle waste warmth?

Thankfully, there are answers for recycling waste warmth.

The perfect is the combination of warmth warmth immediately into the economic procedure, for instance, in trade,, for instance, the warmth leaving the oven may also be presented right into a pregatchetist situated on the backside of the preheating tower “, which has the main function of” too sizzling “uncooked fabrics.

If waste warmth is at a rather low temperature (underneath 100 ° C), it may be reused in an business position to energy different processes or heating rooms – proximity to lack of warmth within the pipes. This warmth will also be inserted into an city community or in a community across the within reach business corporate.

Another choice: produce electrical energy from waste warmth, the usage of natural staff’ thermodynamic cycles. In follow, that is carried out for waste warmth assets at reasonably top temperatures (above 200 ° C), as potency is proscribed: for instance, relating to a manufacturing facility temperature of 200 ° C and cooling within the setting (20 ° C), most potency is 38%.

Two choices to not devour waste warmth from factories: producing electrical energy for the electrical energy community and provide the community community of district heating. Zsolt Biczo, Shutterstock

In the end, warmth pumps can be utilized to lift the temperature stage of waste warmth drift and thus permit its direct exploitation within the business procedure. This feature is promising, as the warmth supply with low temperatures represents 51% of the whole supply.

Home warmth pumps grow to be higher and higher recognized to people, however to people who wish to use and increase to recuperate waste warmth in factories is tougher to use.

Warmth pumps: Resolution for valorizing “low temperature” Supply of waste warmth

The warmth pumps (or “PACS”) permit the temperature to lift the primary that can glance paradoxical: it comes to warmth from the chilly supply to present it with a sizzling supply, thus contrasting the herbal path of power transmission.

We wish to make a opposite transmission via including “work” within the thermodynamic cycle (the activity is in a little while, the type of power, and due to this fact the house warmth pumps have {an electrical} outlet). They seize lots of the power used within the type of energy (warmth) and spend some electrical energy.

Switch from a chilly supply to a sizzling spring is carried out in 4 major steps, defined underneath:

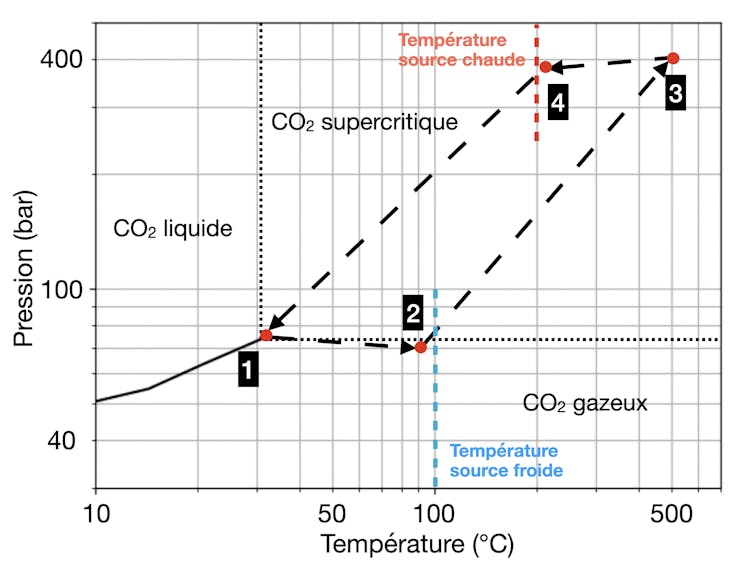

Thermodynamic cycle (Inverse Braitton) the usage of top temperatures warmth pumps utilized by supercritical co₂ to recuperate waste warmth. Alexis Giauque, who were given the creator

In our case, the liquid is “supercritical CO2” (CO2, at top temperature and top drive, behaves in addition to liquid and fuel: it may be subtle via solids akin to fuel and will clear up fabrics akin to liquids). A chilly supply, from which we need to extract warmth, whether or not the warmth warmth drift is from the economic procedure (on tCOLD = 100 ° C); The recent “source” or goal, is at a miles upper temperature (purpose in our venture is sizzling = 200 ° C).

The one power expenditure on this cycle wishes to supply a compressor, which allows liquid movement – in our case, a supercritical CO2 – a key level is roughly 5 instances not up to the power transferred from the HOLESTOR.

So we will “upcicle” warmth, however all warmth may also be returned. As an example, for instance, we reject warmth drift at a temperature simply above 30 ° C. Then again, it’s not simple to quantify the rest warmth as a result of we rely at the ambient temperature, and the temperature of the ambience is 30 ° C, so we’ve recovered the go out drift nearly within the setting, it could be much less within the setting.

Our warmth pumps use CO2 in a supercritical area, as a result of this gives a number of advantages: warmth capability throughout trade with chilly viscosity, low viscosity limits the friction losses (compressors / generators), and there are not any drops (liquid / fuel).

Medical analysis serving the decarbonization of trade

The cycle we simply described (Inverse Braiton cycle of supercritical CO2) is within the middle of the RevCo venture.

However our cooperation desires so as to add warmth recycling gadget, top temperature garage gadget (T ~ 600 ° C), which might permit electrical energy era from this “high quality” warmth “

Our hope is that manufacturers shall be in a position to make a choice from their wishes at any time, to devour a bit electrical energy to make use of them of their business procedure or that warmth is used at 600 ° C to provide electrical energy (most effective waste warmth warmth) and resold it. The cost of electrical energy appears to be bought and resale within the Ecu marketplace, due to this fact, a brand new parameter for restoration of waste warmth. Our optimizations will due to this fact come with an financial size, crucial to appropriating producers of recent technological answers.

To supply an optimized gadget, within the RevCo2 venture, we can enforce detailed experiments for warmth exchangers and methods and simulation gear for a top model that may play the conduct of every of the weather of the whole gadget (turbachines, exchangers and warmth exchangers, and warmth exchangers). Due to the accrued knowledge, a virtual dual is created to finish the whole gadget and can supply checking out of optimum use methods from the technical and financial standpoint.

REVCO2 venture – Building and optimization of reversible supercritical COG for restoration of waste warmth from PEPR (precedence analysis program and gear) Spleen, which was once supported via the Nationwide Analysis Company (ANR) financing analysis analysis in France. The ANR Challenge is to improve and advertise the advance of fundamental and finalized analysis in all disciplines and strengthens the discussion between science and society. To be told extra, see the Anr Internet web page.