To take into consideration a synthetic limb is to take into consideration an individual. It’s an object of contact and movement made for use, person who attaches to the frame and interacts with its person’s global.

Ancient artifacts of prosthetic limbs are some distance got rid of from this lived context. Their customers are long gone. They’re broken – deteriorated via time and publicity to the weather. They’re immobile, saved on show or in museum garage.

But, such artifacts are uncommon direct assets into the lives of historic amputees. We focal point at the equipment amputees utilized in Sixteenth- and Seventeenth-century Europe. There are few information written from amputees’ views at the moment, and those who exist say little about what on a regular basis existence with a prosthesis used to be like.

Engineering gives historians new equipment to inspect bodily proof. That is in particular vital for the find out about of early trendy mechanical fingers, a brand new more or less prosthetic generation that gave the impression on the flip of the Sixteenth century. Many of the artifacts are of unknown provenance. Many paintings best in part and a few in no way. Their sensible purposes stay a thriller.

However computer-aided design device can assist students reconstruct the artifacts’ interior mechanisms. This, in flip, is helping us know how the items as soon as moved.

Much more thrilling, 3-D printing shall we students create bodily fashions. Moderately than imagining how a Renaissance prosthesis labored, students can bodily check one. It’s a type of investigation that opens new chances for exploring the advance of prosthetic generation and person enjoy throughout the centuries. It creates a path of breadcrumbs that may convey us nearer to the on a regular basis reviews of premodern amputees.

However what does this paintings, which brings in combination two very other fields, appear to be in motion?

What follows is a glimpse into our enjoy of collaboration on a workforce of historians and engineers, instructed throughout the tale of 1 week. Running in combination, we shared a style of a Sixteenth-century prosthesis with the general public and realized a lesson about people and generation within the procedure.

A historian encounters a damaged style

THE HISTORIAN: On a cloudy day in past due March, I walked into the College of Alabama Birmingham’s Middle for Instructing and Finding out keeping a weatherproof case and brimming with pleasure. Nestled inside the case’s foam inserts used to be a functioning 3-D-printed style of a 500-year-old prosthetic hand.

Fifteen mins later, it broke.

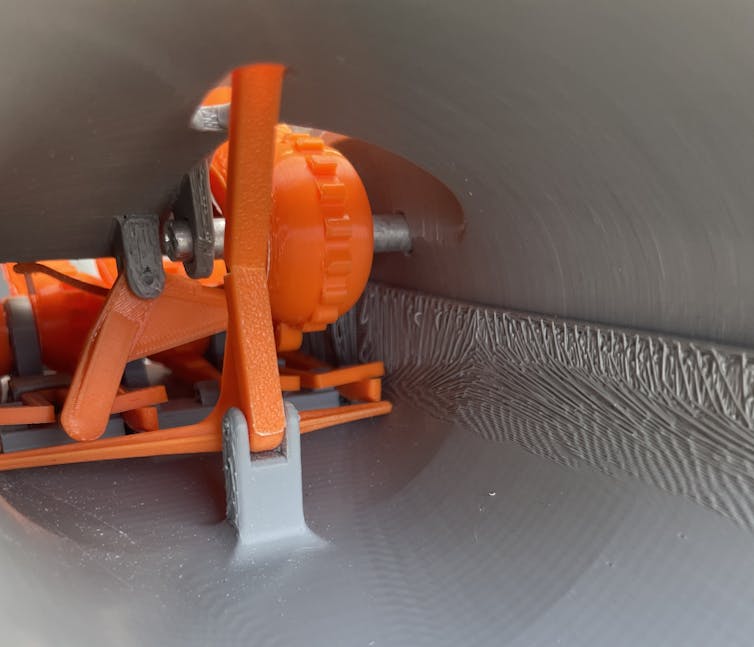

This 3-D-printed style of a Sixteenth-century hand prosthesis has operating mechanisms.

Heidi Hausse, CC BY-SA

For 2 years, my workforce of historians and engineers at Auburn College had labored tirelessly to show an concept – recreating the mechanisms of a Sixteenth-century artifact from Germany – into fact. The unique iron prosthesis, the Kassel Hand, is certainly one of roughly 35 from Renaissance Europe identified these days.

As an early trendy historian who research those artifacts, I paintings with a mechanical engineer, Chad Rose, to seek out new techniques to discover them. The Kassel Hand is our case find out about. Our objective is to be informed extra in regards to the lifetime of the unknown one that used this artifact 500 years in the past.

The usage of 3-D-printed fashions, we’ve run experiments to check what forms of actions its person may have carried out with it. We modeled in affordable polylactic acid – plastic – to make this fragile artifact obtainable to somebody with a consumer-grade 3-D printer. However ahead of sharing our recordsdata with the general public, we had to see how the style fared when others treated it.

A call for participation to visitor lecture on our experiments in Birmingham used to be our alternative to just do that.

We introduced two fashions. The primary liberate lever broke first in a single after which the opposite. This lever has an inside triangular plate attached to a skinny rod that juts out of the wrist like a cause. After urgent the palms right into a locked place, pulling the cause is the one method to loose them. If it breaks, the palms turn out to be caught.

The skinny rod of the principle liberate lever snapped on this style.

Heidi Hausse, CC BY-SA

I used to be baffled. Throughout checking out, the style had lifted a 20-pound simulation of a chest lid via its fingertips. But, the primary time we shared it with a basic target audience, a mechanism that had by no means damaged in checking out merely snapped.

Used to be it a printing error? Subject matter defect? Design flaw?

We consulted our Hand Whisperer: our lead scholar engineer whose really feel for a way the style works seems every now and then preternatural.

An engineer turns into a hand whisperer

As a mechanical engineering graduate scholar focusing on additive production, recurrently referred to as 3-D printing, I discover learn how to use this generation to reconstruct historic mechanisms. Over the 2 years I’ve labored in this undertaking, I’ve come to understand the Kassel Hand style neatly. As we fine-tuned designs, I’ve created and edited its computer-aided design recordsdata – the virtual 3-D buildings of the style – and revealed and assembled its portions numerous instances.

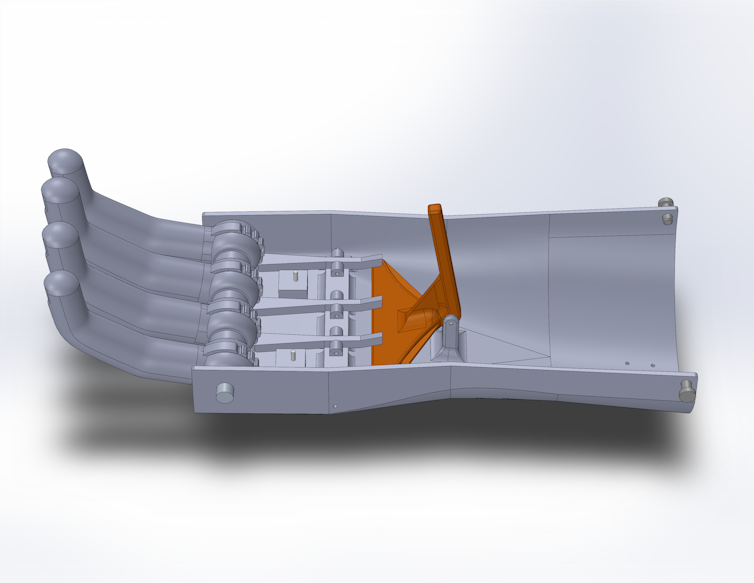

This view of the computer-aided design record of a reinforced model of the style, which contains ribs and fillets to enhance the plastic subject material, highlights the principle liberate lever in orange.

Peden Jones, CC BY-SA

Inspecting portions midassembly is a a very powerful checkpoint for our prototypes. This high quality keep watch over catches, corrects and forestalls any defects, similar to misprinted or broken portions. It’s a very powerful for growing constant and repeatable experiments. A brand new style model or element exchange by no means leaves the lab with out passing rigorous inspection. This procedure way there are methods this style has behaved over the years that the remainder of the workforce hasn’t ever noticed. However I’ve.

So once I heard the discharge lever had damaged in Birmingham, it used to be simply every other Thursday. Whilst it had by no means snapped after we examined the style on folks, I’d noticed it ruin a lot of instances whilst acting assessments on parts.

Our style reconstructs the Kassel Hand’s authentic steel mechanisms in plastic.

Heidi Hausse, CC BY-SA

Finally, the style is constituted of somewhat susceptible polylactic acid. Possibly probably the most tough a part of our paintings is creating a plastic style as sturdy as conceivable whilst protecting it visually in step with the 500-year-old authentic. The iron rod of the artifact’s lever can take care of extra power than our plastic model, a minimum of 5 instances the yield power.

I suspected the lever had snapped as a result of folks pulled the cause too some distance again and too temporarily. The problem, then, used to be to stop this. However redesigning the lever to be thicker or a unique form would make it much less just like the historic artifact.

This raised the query: Why may just I exploit the style with out breaking the lever, however no person else may just?

The workforce makes a plan

THE TEAM: A flurry of dialogue ended in rising consensus – the crux of the problem used to be now not the style, it used to be the person.

The unique Kassel Hand’s wearer would have realized to make use of their prosthesis via follow. Likewise, our workforce had realized to make use of the style over the years. During the means of design and building, prototyping and printing, we had been inadvertently practising learn how to function it.

We had to train others to do the similar. And this known as for a two-pronged method.

Point of view on the use of the Kassel Hand, as a contemporary prosthetist.

The engineers reexamined the outlet wherein the discharge cause poked out of the style. They proposed shortening it to restrict how some distance again customers may just pull it. After we checked how this modification would have an effect on the style’s accuracy, we discovered {that a} smaller opening used to be in reality nearer to the artifact’s dimensions. Whilst the bigger opening have been essential for an previous model of the discharge lever that had to go back and forth farther, now it best brought about issues. The engineers started working.

The historians, in the meantime, created plans to report and proportion the quite a lot of tactics to running the style the workforce hadn’t discovered it had honed. To show any person at house learn how to function their very own reproduction, we filmed a brief video explaining learn how to lock and liberate the palms and troubleshoot when a finger sticks.

Checking out the plan

Precisely one week after what we known as “the Birmingham Break,” we shared the style with a basic target audience once more. This time we visited a colleague’s historical past magnificence at Auburn.

We introduced 4 copies. Every had an insert to shorten the outlet across the cause. First, we performed our new educational video on a projector. Then we grew to become the fashions over to the scholars to check out.

The workforce introduced those 4 fashions with inserts to shorten the outlet beneath the discharge cause to check with a basic target audience of undergraduate and graduate scholars.

Heidi Hausse, CC BY-SA

The end result? Now not a unmarried damaged lever. We publicly introduced the undertaking on time table.

The method of introducing the Kassel Hand style to the general public highlights that simply because the Sixteenth-century amputee who wore the artifact needed to discover ways to use it, one will have to discover ways to use the 3-D-printed style, too.

This is a potent reminder that generation isn’t just an issue of mechanisms and design. It’s essentially about folks – and the way folks use it.